Introduction

Precision engineering is at the heart of modern industrial processes. It’s the area that makes sure machines run smoothly efficiently and efficiently, with little wear and wear and tear. In the middle of a lot of precision-engineered systems are bearings that reduce friction and improve efficiency. In particular the taper bearings are emerging as pivotal elements, leading an unnoticed revolution in engineering precision around the world. But what happens in Pakistan? Let’s explore the taper bearing Pakistan industry and discover their major impact on the sector.

Understanding Taper Bearing Pakistan

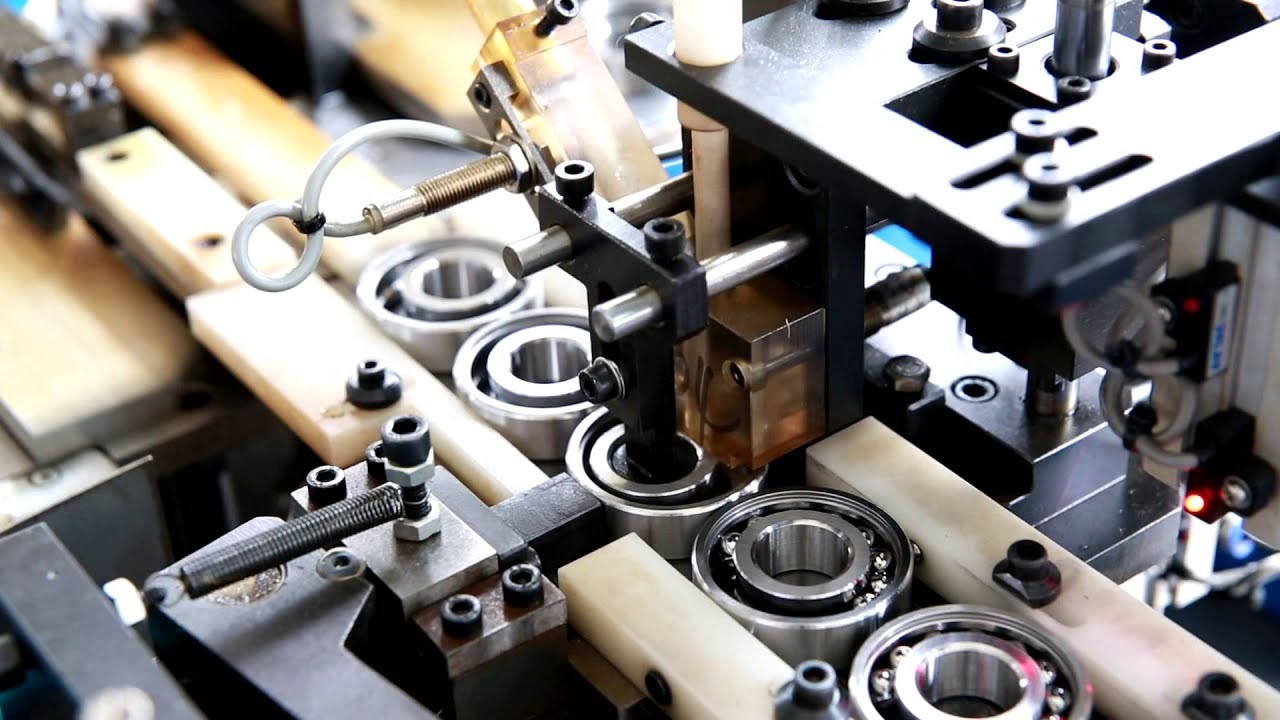

Definition and Structure

Taper bearing Pakistan, also referred to as tapered roller bearings are a form of bearing with a rolling element specifically designed to handle the radial and axial loads. They comprise of inner and outer raceways and tapered rollers set in a cone-like configuration. The unique design of these raceways lets them support huge loads and endure high amounts of strain, which makes them vital in heavy equipment as well as automotive use.

How They Work

The tapered rollers of these bearings are placed at an angle relative to the bearing’s axis, which assists in spreading loads more evenly. In motion, the rollers join to a common point along the bearing’s axis. This reduces stress and wearing. This design allows for effective handling of loads that are combined and makes them perfect for applications that require durability and accuracy.

The Evolution of Taper Bearings

Historical Background

The idea of taper bearings dates to the latter part of the 19th century when engineers were looking for methods to boost the effectiveness in industrial machines. Through the years technological advances have greatly improved their appearance and function and made them more durable and durable.

Technological Advancements

From the introduction of high-quality steel, to the development of advanced lubrication systems taper bearing Pakistan has seen constant improvement. Modern techniques of manufacturing, like precise grinding, as well as computer-aided design (CAD) have further improved their performance and dependability.

Why Taper Bearings?

Advantages Over Other Bearings

Taper bearing Pakistan business provide a number of advantages over other kinds of bearings. Their capacity to handle heavy load axial and radial simultaneously is what makes them highly reliable and versatile. They also offer additional more efficient distribution of loads, which reduces the chance of premature failure, and also increasing the longevity of machinery.

Applications in Various Industries

Taper bearings are used extensively in various industries, including aerospace, automotive industrial machinery, even in high-end applications such as mines and construction. Their durability and versatility make them a popular choice for any task that requires extreme precision and long-lasting durability.

Taper Bearings Pakistan

Growth of the Bearings Industry in Pakistan

Pakistan has witnessed a dramatic expansion in the bearings industry that is fueled by the increasing industrialization and a demand for top-quality machinery components. The production of taper bearings has increased in order to meet both local requirements as well as export markets.

Key Manufacturers and Suppliers

A number of important players control the market for taper bearings in Pakistan. Companies such as NTN Bearings, SKF Pakistan as well as local producers made their mark as top-of-the-line in the supply of high-quality bearings to different industries.

Precision Engineering in Pakistan

Definition and Scope

The field of precision engineering within Pakistan is a variety of tasks, ranging from the production of components for industrial machinery to manufacturing precise equipment and tools. This is a crucial sector to the country’s economic growth and growth.

Impact on the National Economy

The sector of precision engineering significantly aids the economy of Pakistan by creating jobs, encouraging creativity, and helping in the manufacturing of high-end products. The growth of bearings with taper is testimony to Pakistan’s increasing capabilities in this area.

Innovations in Taper Bearings Technology

Material Improvements

Modern advances in the field of material science have led the introduction of premium alloys and composites in taper bearings. These materials provide increased durability, strength and resistance to corrosion and wear.

Design Innovations

Modern taper bearings come with new designs that maximize the distribution of load and decrease friction. Modeling and computer simulation have played an important role in these advances.

Manufacturing Techniques

Innovative manufacturing techniques, including precision milling and additive manufacturing have revolutionized the manufacturing of bearings with taper. These methods assure the highest level of accuracy and reliability in the dimensions of bearings and their performance.

Quality Standards and Certifications

International Standards

Taper bearings must conform to strict international standards like ISO as well as ANSI. The standards warrant they satisfy certain performance and safety requirements that guarantee their durability and effectiveness.

Compliance in Pakistan

Pakistani manufacturers have accepted the international standards and are ensuring that their products are competitive on both the local and global market. The compliance with these standards is vital to keeping quality and ensuring trust among customers.

Challenges Faced by the Industry

Raw Material Supply

The availability and quality of the raw materials is crucial to produce quality taper bearings. Variations in prices and supply could pose a significant challenge for producers.

Skilled Workforce Availability

Making precision-engineered parts requires skilled workers. Instructing and keeping experts in engineers and technicians is a constant struggle for the sector.

Technological Barriers

Staying up to date with technological advances and implementing new manufacturing methods isn’t easy, particularly for small businesses with small resources.

Government Policies and Support

Regulatory Framework

The Pakistani government has introduced policies that support the development of precision engineering industry. This includes regulations to warrant the safety and quality of products.

Incentives for the Industry

Numerous incentives, including subsidies and tax breaks are offered to encourage investments in precision engineering as well as the bearing business. These initiatives benefit in encouraging the development of innovation and growth.

Future of Taper Bearings Pakistan

Growth Projections

The future is bright for the taper bearings sector in Pakistan. With the continuous industrialization of Pakistan and the growing demand for premium components The industry is poised for rapid expansion.

Emerging Trends

New trends like the use of intelligent manufacturing methods and the creation of environmentally friendly bearings are expected to determine how we approach the sector.

Case Studies

Erfolg Stories of Pakistani Businesses

A number of Pakistani businesses have experienced amazing successes in the field of bearings. For example the local company has partnered with international companies to increase their product’s quality and broaden the market.

Impact of Taper Bearings on Local Industries

The availability of top-quality taper bearings has significantly impacted different local industries, from heavy machinery to automotive increasing their efficiency and reliability.

Environmental Impact

Sustainable Practices in Manufacturing

Implementing sustainable manufacturing practices when making taper bearings is vital to the least environmental impacts. This means with sustainable materials, and reducing waste.

Reducing Carbon Footprint

The effort is underway to decrease the environmental footprint associated with production of bearings through efficient energy use and the utilization in renewable sources of energy.

Consumer Awareness and Education

Importance of Quality Bearings

The importance of educating consumers on the benefits of together quality bearings is vital. Good bearings warrant greater performance, longer life and the safety of machines.

How to Choose the Right Bearing

The best bearing requires understanding the particular demands of the application including speed, capacity, and the environmental conditions.

Conclusion

The industry of taper bearing Pakistan is experiencing a quiet revolution, fueled by advances in precision engineering and a rapid development in industrial processes. With continuous innovation and the support of the government it is looking promising for this important sector. As Pakistan advances in precision engineering and taper bearings, they will play a significant part in shaping Pakistan’s industrial environment.

FAQs

What can taper bearings be utilized in?

Taper bearings are mostly used to manage both axial and radial loads in machinery, which makes them suitable for aerospace, automotive or heavy machineries.

What makes taper bearings distinguish themselves from the other types of bearings?

Unlike other bearings that are used, taper bearings can withstand massive load loads in combination and give greater load distribution that reduces wear and extends the life of machinery.

What companies make taper bearings from Pakistan?

Key manufacturers in Pakistan include NTN Bearings, SKF Pakistan as well as a variety of local businesses that specialize in premium bearings.

What’s the main challenges facing the industry of taper bearings within Pakistan?

Major challenges are the supply of raw materials and a dearth of skilled workers and the need to keep pace with the latest technological advances.

What are the outlooks for the industry of taper bearings of Pakistan?

The industry is expected to expand significantly because of the growing industrialization, technological advancements and the favorable policies of the government.