The importance of pipelines in transporting oil, gas, and other essential substances across vast distances cannot be overemphasized. However, pipeline integrity is a critical issue that must be addressed to ensure the safety and efficiency of these transportation systems. Pipeline investigation, therefore, becomes a significant aspect of pipeline management. With the advent of new technologies, pipeline inspection has seen a significant transformation, leading to increased safety, efficiency, and cost-effectiveness.

Pipeline investigation refers to the systematic examination and assessment of pipelines, typically in the context of the oil and gas industry or water distribution systems. This process involves inspecting the condition, integrity, and performance of pipelines to ensure they operate safely and efficiently. Various techniques, such as visual inspections, non-destructive testing, and remote sensing technologies, are used to detect defects, corrosion, leaks, or other issues within the pipeline infrastructure. The results of pipeline investigations are crucial for maintenance, repair, and decision-making to prevent accidents and ensure the reliable transport of fluids.

Pipeline investigation is an incredibly crucial aspect of maintaining and ensuring the longevity of our infrastructure. It’s all about delving into the intricate network of pipelines that make up our cities and industries. This examination is not just about detecting leaks and blockages but also about understanding the inner workings of these pipelines, and identifying potential issues before they become major problems.

I. The Importance of Pipeline Investigation

Pipeline investigation is critical in maintaining the integrity and safety of pipelines. It involves the examination of pipelines to detect faults, leaks, and other potential issues that could compromise their efficiency. A thorough pipeline inspection ensures that any potential issues are identified and rectified before they escalate into significant problems. Pipeline investigation plays a crucial role in preventing disasters, environmental pollution, and economic losses. Ensuring the safety of pipelines is a top priority. Investigation helps identify and address potential hazards, reducing the risk of accidents, leaks, or explosions. This is critical for protecting both the environment and human lives.

Over time, pipelines can degrade due to corrosion, wear, or other factors. Investigating their condition allows for early detection of issues, preventing catastrophic failures and minimizing costly repairs. Leaks or ruptures in pipelines can lead to environmental disasters, such as oil spills or contamination of water sources. Investigative measures help detect and prevent such incidents, reducing environmental damage.

II. Traditional Methods of Pipeline Inspection

The traditional methods of pipeline inspection involve visual inspection and pressure testing. These methods, while effective to a certain degree, have their limitations. Visual inspection, for instance, can only detect surface defects and cannot identify internal issues. Pressure testing, on the other hand, involves shutting down the pipeline, which leads to operational downtime and revenue loss.

Traditional methods of pipeline inspection involve physical examination and assessment of pipelines using manual techniques and equipment. While these methods have been used for decades, they continue to play a crucial role in ensuring the integrity and safety of pipeline systems.

III. The Revolution in Pipeline Inspection Technology

Advancements in technology have revolutionized the process of pipeline investigation. Modern inspection technology, such as smart pigs, use advanced sensors to detect defects both on the surface and internally. These devices can identify a variety of issues, including corrosion, leaks, and structural defects. Moreover, they can operate while the pipeline is in service, eliminating the need for operational downtime.

The field of pipeline inspection has undergone a remarkable revolution thanks to advancements in technology. Traditional methods, while still important, have been complemented and, in some cases, replaced by cutting-edge technologies that offer enhanced accuracy, efficiency, and safety.

IV. The Role of Robots in Pipeline Inspection

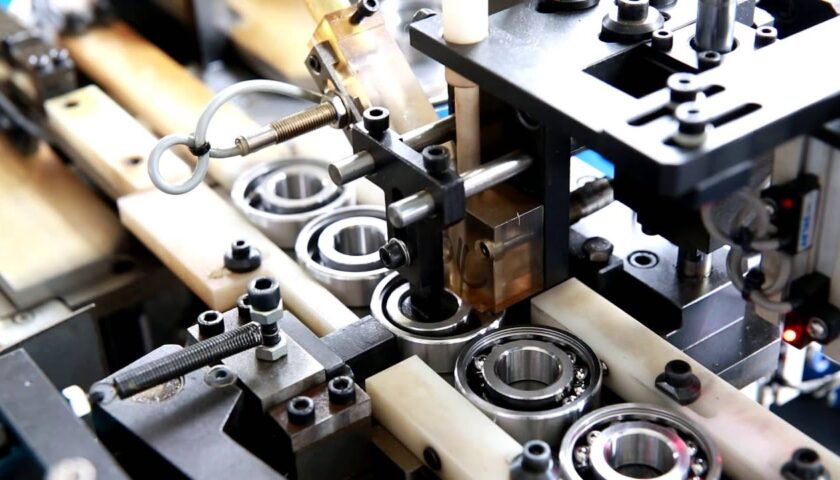

One of the most significant advancements in pipeline inspection technology is the use of robots. Pipeline inspection robots, equipped with high-resolution cameras and sensors, can traverse the pipeline, capturing detailed images and data for analysis. This technology allows for a more thorough and accurate inspection, even in hard-to-reach areas. Pipeline investigation is an integral aspect of maintaining the integrity and safety of our pipeline systems. This process involves the rigorous examination of pipes to detect potential issues such as leaks, rust, corrosion, or other structural defects. Traditionally, this task was labor-intensive, time-consuming, and fraught with risks. However, in recent years, we’ve seen a significant shift in how these investigations are conducted, thanks to the advent of robotics.

Robots play a pivotal role in modern pipeline inspection, offering numerous advantages in terms of efficiency, accuracy, and safety. Their deployment has transformed the way pipelines are assessed and maintained. Robots, particularly tethered or remotely operated ones, can access and navigate areas of pipelines that are difficult or dangerous for humans to reach. This includes inspecting underwater pipelines, traversing challenging terrains, and entering confined spaces.

V. The Future of Pipeline Investigation

The future of pipeline investigation looks promising, with new technologies continually emerging. For instance, the use of drone technology and artificial intelligence in pipeline inspection is becoming more prevalent. These technologies promise to further enhance the accuracy and efficiency of pipeline investigations, ensuring the safety and integrity of our vital pipeline infrastructure.

The future of pipeline investigation will be characterized by an integration of cutting-edge technologies, a commitment to environmental stewardship, and a focus on maintaining the safety and reliability of critical infrastructure. These developments will not only enhance the efficiency of inspection processes but also contribute to the sustainability and resilience of pipeline systems worldwide.

Conclusion

In conclusion, the evolution of pipeline inspection technology has greatly enhanced the process of pipeline investigation. From traditional methods to advanced technologies, pipeline inspection has come a long way. As technology continues to advance, we can expect even more improvements in pipeline investigation, ensuring the safety, efficiency, and integrity of our pipelines. It’s an exciting time for the industry, and we can’t wait to see what the future holds.

The revolution in pipeline investigation technology is not just about making the process more efficient. It’s about ensuring the safety of our environment, the well-being of our communities, and the sustainability of our economy. The future of pipeline investigation is bright, and we are just at the beginning of this exciting journey.