In the bustling industrial landscape of Valencia, a city renowned for its technological advancements and engineering expertise, a particular group of craftsmen stands out: the high precision mold makers. These skilled artisans are the backbone of numerous industries, from automotive to medical devices, where even a micrometer’s deviation can lead to failure. This article delves into the world of Best High Precision Mold Making In Valencia, exploring their meticulous craft, the sophisticated technology they employ, and the significant role they play in global manufacturing.

1. Expertise in Design

High-precision molds allow plastic products to be produced with the same consistency, drastically reducing quality variations and product defects. This is a crucial aspect in ensuring customer satisfaction and increasing business competitiveness.

Precise molds are a vital component in the manufacture of many products, from encapsulated electric coils and protective helmets to car bumpers and medical syringes. Several different plastic production techniques can create these items, but precision molds offer the most reliable and cost-efficient results.

Custom manufacturer of injection, insert and over-molded parts using a wide range of materials such as acrylonitrile butadiene styrene (ABS), acrylic, thermoplastic, polycarbonate, nylon and microcellular. Capabilities include cold runner, hot runner and multi-cavity injection molding and vacuum forming, CNC machining, metal finishing, laser and hand metrology inspection, assembly, packaging and warehousing. Serves appliance, agricultural, automotive, electronics, aerospace, marine, HVAC and medical industries.

Valencia Plastics Inc in Valencia, CA produces plastic injection and blow molded components and also offers design engineering, manufacturing analysis and tooling design and construction. The company can provide prototypes through CNC and EDM methods, as well as CAD/CAM design services.

2. Precision CNC Machining

Precision CNC machining is the process of using computer-guided tools to cut and shape raw materials. It uses coded programming instructions to automate and monitor the movement of cutting tools, so manufacturers can achieve complex designs and tolerances that would be difficult to produce manually. This technology works well with a variety of materials, including aluminum, brass, plastics, and stainless steel.

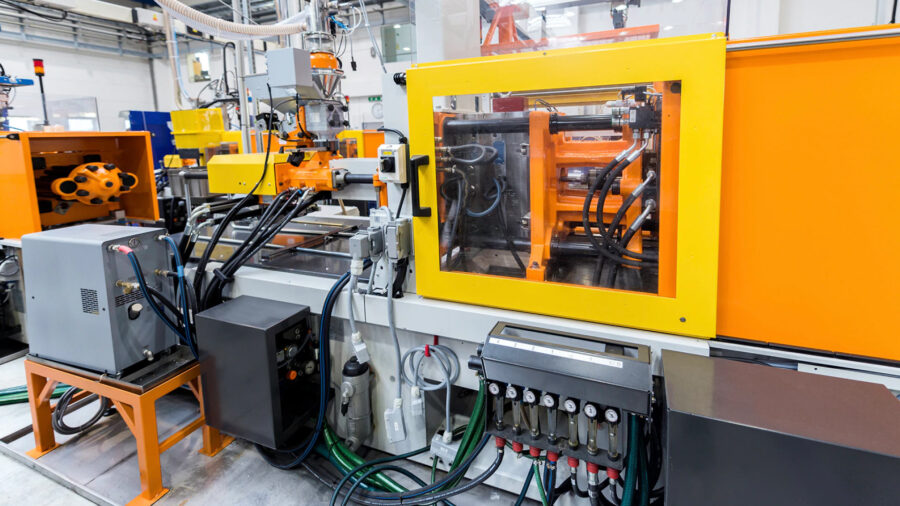

3. Injection Molding

Injection molding is a very fast and effective manufacturing process, allowing for large numbers of identical plastic components to be produced in relatively short periods. But it is not without its challenges, particularly when it comes to maximizing precision and quality.

The injection molding process itself is relatively straightforward, but the molds must be fabricated using a high degree of skill and care, as they are custom-made from metal that will be subjected to many heating and cooling cycles over the course of a production run. This means that they need to be able to withstand extremely high levels of heat and pressure, while still maintaining a precise shape.

4. Assembly

For complex, high-performance plastic injection molded products with demanding tolerances, assembly is a crucial step. The right tools and techniques ensure that each component is positioned properly, with no gaps or overlaps. This makes it important to choose a plastic manufacturer with the capabilities needed for assembly, and who is familiar with the challenges and requirements of precision injection molding.

High Precision Mold Making In Valencia offer expert plastic injection molded assembly services. They can perform value added operations such as coating, testing, and packaging — all within the mold production cycle. These additional steps can help you reduce lead times and the need for post-mold handling, saving you time and money on manufacturing and distribution. This turnkey approach also provides you with a finished product ready for resale or distribution.

The Art and Science of Mold Making

Mold making is both an art and a science, requiring a deep understanding of materials, a keen eye for detail, and a mastery of modern engineering techniques. In Valencia, precision mold makers combine traditional craftsmanship with cutting-edge technology to produce molds that meet exact specifications.

Industries Served by Valencia’s Mold Makers

The molds produced by Valencia’s craftsmen are crucial components in a variety of sectors:

1. Automotive Industry

In the automotive sector, the demand for precision is unyielding. Valencia’s mold makers create parts for everything from engine components to intricate dashboard buttons. The high standards in this industry push mold makers to constantly refine their processes and ensure that each mold is perfect.

2. Medical Devices

Accuracy is critical when it comes to medical devices. Molds used for medical equipment, such as surgical instruments and implantable devices, must meet stringent regulatory standards for safety and reliability. The mold makers of Valencia excel in this area, producing molds that adhere to precise medical specifications.

3. Consumer Electronics

The consumer electronics industry is driven by the demand for sleek, durable products. Mold makers in Valencia contribute to this field by producing molds for smartphone cases, laptop parts, and other high-tech gadgets. Their ability to work at such fine tolerances allows for the production of increasingly thinner and more durable devices. For More Information

Challenges and Innovations

Despite their expertise, Valencia’s mold makers face several challenges:

1. Maintaining Precision at Scale

One of the biggest challenges is maintaining the same level of precision as production scales up. This requires not only great skill but also constant vigilance and quality control measures to ensure that every mold and every part remains consistent.

2. Material Innovations

As new materials are developed, mold makers must continually adapt their methods to handle these materials without compromising the quality of the finished product. This might mean investing in new machines or learning new techniques that can handle the unique properties of advanced materials.

3. Environmental Considerations

Environmental sustainability is becoming increasingly important. Valencia’s mold makers are exploring ways to reduce waste and energy consumption in their processes, and to recycle materials wherever possible.

Conclusion

High Precision Mold Making In Valencia are a vital part of the modern manufacturing ecosystem, providing the necessary components that industries depend on to create detailed and durable products. Their commitment to precision, coupled with a willingness to embrace new technologies and methods, ensures that they remain at the forefront of the mold-making industry. Through their craft, these artisans not only contribute to the local economy but also play a crucial role in the global market, where precision and reliability are paramount. Thank visiting trendingblogsweb.com