Brazing, a technique of joining metal components using a filler material called brazing alloy, is a critical process across various industries. From aerospace engineering to automotive manufacturing, brazing plays a significant role in creating durable and high-performance assemblies. Central to the success of brazing is the choice of brazing alloys, which directly influence the strength, durability, and overall performance of the joints. In this exploration, we delve into the world of brazing alloys, uncovering their characteristics, applications, and the factors that contribute to their effectiveness in diverse settings.

Understanding Brazing Alloys

Brazing alloys are metal alloys with a melting point lower than that of the base metals being joine. This characteristic allows the alloy to flow. Fill the gap between the components to be joine without melting the base metals. Common base metals in brazing applications include steel, stainless steel, copper, brass, and aluminum. The choice of brazing alloy depends on several factors, including the base metals, joint design, service conditions, and desired mechanical properties.

Strength and Durability

One of the primary considerations in brazing alloy selection is the strength and durability of the joint. Brazed joints must withstand mechanical loads, thermal cycling, corrosion, and other environmental factors. The strength of a braze joint is influenced by the compatibility between the brazing alloy and the base metals. As well as the joint design and brazing process parameters.

Different brazing alloys offer varying levels of strength and durability. For instance, silver-base alloys are known for their high strength and excellent corrosion resistance. Making them suitable for critical applications in aerospace and medical industries. Copper-phosphorus alloys, on the other hand, are preferred for brazing copper. Copper alloys due to their ability to wet and bond well with copper surfaces.

Performance Characteristics

In addition to strength and durability, brazing alloy exhibit various performance characteristics that impact their suitability for specific applications. These characteristics include:

- Fluidity: The ability of the brazing alloy to flow and wet the base metal surfaces is crucial for achieving sound and uniform joints. Alloys with good fluidity ensure proper penetration into the joint, minimizing the risk of defects such as voids and incomplete bonding.

- Capillary Action: Capillary action plays a vital role in brazing, especially in tight-fitting joints. Capillary attraction allows the molten brazing alloy to be drawn into the joint by surface tension. Ensuring intimate contact between the mating surfaces and facilitating the formation of a strong bond.

- Corrosion Resistance: Depending on the application, brazed joints may be expose to corrosive environments. Brazing alloys with inherent corrosion resistance or those that form protective oxide layers upon exposure to air can enhance the longevity of the joints in such conditions.

- Temperature Stability: Some brazing alloys are designed to maintain their mechanical properties at elevated temperatures, making them suitable for applications where the joint may be subjected to high operating temperatures or thermal cycling.

Applications of Brazing Alloys

Brazing alloys find widespread use in various industries and applications, including:

- Automotive: Braze joints are commonly found in automotive heat exchangers, such as radiators and condensers. Brazing alloys with high thermal conductivity and corrosion resistance are preferred for these applications to ensure efficient heat transfer and long-term durability.

- HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration): Brazing is extensively use in the manufacture of HVACR components, including copper tubing assemblies and aluminum heat exchangers. Alloys tailored for brazing copper and aluminum are essential for creating leak-tight and durable joints in these systems.

- Electronics: In electronic assembly applications, brazing is employe to join components such as copper traces on circuit boards and heat sinks to semiconductor devices. Brazing alloys with low melting temperatures and minimal heat input are desirable to prevent damage to sensitive electronic components.

- Aerospace: The aerospace industry relies on brazing for fabricating critical components like turbine blades, fuel lines, and structural assemblies. Brazing alloys capable of withstanding high temperatures and extreme environmental conditions are indispensable for ensuring the structural integrity and performance of aerospace components.

- Medical Devices: Brazing plays a crucial role in the manufacture of medical devices and implants, where biocompatibility, corrosion resistance, and mechanical strength are paramount. Precise control over joint formation and the use of biocompatible brazing alloys are essential to meet the stringent requirements of medical applications.

Factors Influencing Brazing Alloy Selection

Several factors influence the selection of brazing alloys for a particular application:

- Base Metal Compatibility: The brazing alloy must be compatible with the base metals being joine to ensure proper wetting and bonding. Consideration is given to metallurgical compatibility, thermal expansion coefficients. The formation of intermetallic compounds at the joint interface.

- Service Conditions: The operating environment and service conditions, including temperature, pressure, mechanical loads, and exposure to corrosive agents, dictate the choice of brazing alloy. Alloys with the appropriate mechanical properties and corrosion resistance for the intende service life are selecte to ensure optimal performance.

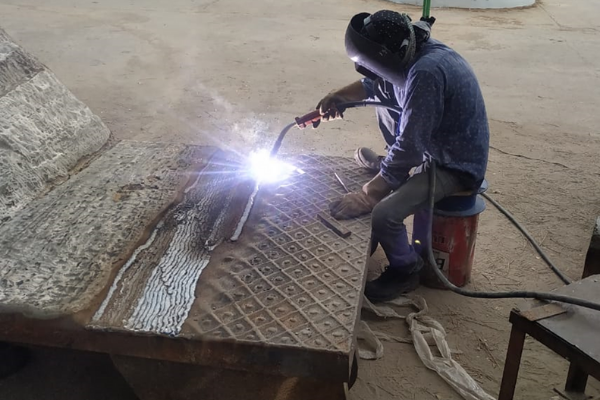

- Brazing Method: The brazing method employed, whether it’s torch brazing, furnace brazing, induction brazing, or vacuum brazing, influences the selection of brazing alloys. Each brazing process has its own set of parameters, such as heating rate, atmosphere control. Cooling rate, which may affect the performance of the brazing alloy.

- Cost Considerations: Cost-effectiveness is an important factor in alloy selection, especially for high-volume production applications. Balancing the performance requirements with the cost of the brazing alloy. Associated processing costs is essential to achieve the desire balance between quality and affordability.

Brazing alloys play a pivotal role in various industries, offering a versatile solution for joining different metals. Whether in aerospace, automotive, or electronics, brazing alloys serve as the binding agent, facilitating strong, durable connections. Understanding the applications, types, and techniques of brazing alloys is essential for engineers, metallurgists, and manufacturers. This comprehensive guide explores the fundamentals of brazing alloys. Shedding light on their diverse applications, different types available. The techniques employed for successful brazing operations.

Conclusion

Brazing alloy play a crucial role in joining metal components across a wide range of industries. Offering strength, durability, and performance in diverse applications. The selection of the right brazing alloy is essential to ensure the integrity. Reliability of brazed joints under various operating conditions. By understanding the characteristics, applications. Factors influencing brazing alloy selection, engineers and manufacturers can optimize the brazing process to meet the demands of modern manufacturing and engineering challenges.