In recent years, businesses have been under increasing pressure to adopt sustainable packaging solutions. As environmental concerns become a top priority for consumers and regulatory bodies, companies are seeking alternatives to traditional plastic and Styrofoam packaging. Molded pulp support has emerged as a preferred choice due to its biodegradable and recyclable nature, making it an eco-friendly alternative that aligns with corporate sustainability goals.

Moreover, molded pulp support is derived from renewable resources such as recycled paper and cardboard. Unlike plastic packaging, which takes centuries to decompose, molded pulp can break down naturally within weeks, reducing landfill waste. Businesses that switch to molded pulp packaging not only reduce their carbon footprint but also improve their brand image by demonstrating a commitment to environmental responsibility.

Cost-Effective and Efficient Shipping Solutions

Cost efficiency plays a significant role in a business’s decision to switch packaging materials. Molded pulp support is not only affordable but also reduces overall shipping expenses. Its lightweight nature minimizes transportation costs, allowing companies to save on freight charges. Additionally, molded pulp packaging is designed to provide excellent protection for products, reducing damage rates and the associated costs of returns and replacements.

Businesses also benefit from the streamlined manufacturing process of molded pulp packaging. Since it is formed using precise molds, there is minimal material wastage, making production highly efficient. As supply chain efficiency becomes crucial in today’s competitive market, molded pulp support provides an optimal balance between cost savings and product protection, making it an attractive solution for shipping needs.

Superior Product Protection and Versatility

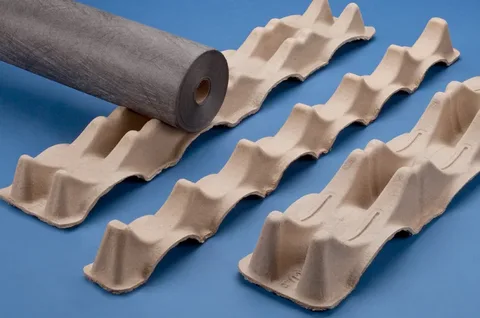

One of the primary concerns in shipping logistics is ensuring that products arrive at their destination undamaged. Molded pulp support offers excellent shock absorption and cushioning, making it ideal for protecting fragile items such as electronics, glassware, and medical supplies. Its structure is designed to absorb impact and distribute pressure evenly, minimizing the risk of breakage.

In addition to protection, molded pulp packaging is highly versatile. It can be customized to fit various product shapes and sizes, ensuring a snug fit that prevents movement during transit. Unlike traditional packaging materials, which often require additional fillers and inserts, molded pulp support provides an all-in-one solution that simplifies packaging while maintaining product integrity.

Compliance with Environmental Regulations and Consumer Expectations

Governments around the world are implementing stricter regulations on single-use plastics and non-biodegradable packaging. Businesses that fail to comply with these new policies face potential fines and reputational risks. Molded pulp support helps companies stay ahead of regulatory requirements by offering a packaging solution that meets environmental standards.

Furthermore, consumer preferences are shifting towards eco-friendly products and packaging. Studies show that modern consumers are more likely to support brands that prioritize sustainability. By adopting molded pulp packaging, businesses not only comply with legal requirements but also cater to the growing demand for environmentally conscious shipping solutions, gaining a competitive advantage in the market.

Innovation and Future Trends in Molded Pulp Packaging

The packaging industry is continuously evolving, and innovations in molded pulp technology are making it even more attractive to businesses. Advanced manufacturing techniques now allow for greater precision in molding, enabling the creation of intricate designs and enhanced protective features. Additionally, the use of water-resistant coatings and improved durability ensures that molded pulp packaging can be used for a wider range of products, including food and beverage items.

Looking ahead, the demand for molded pulp support is expected to grow as more industries recognize its benefits. Companies investing in sustainable packaging solutions today will be well-positioned to adapt to future regulations and consumer preferences. As technology advances, molded pulp support will continue to play a crucial role in the shipping industry, offering businesses a sustainable, cost-effective, and efficient alternative to traditional packaging materials.