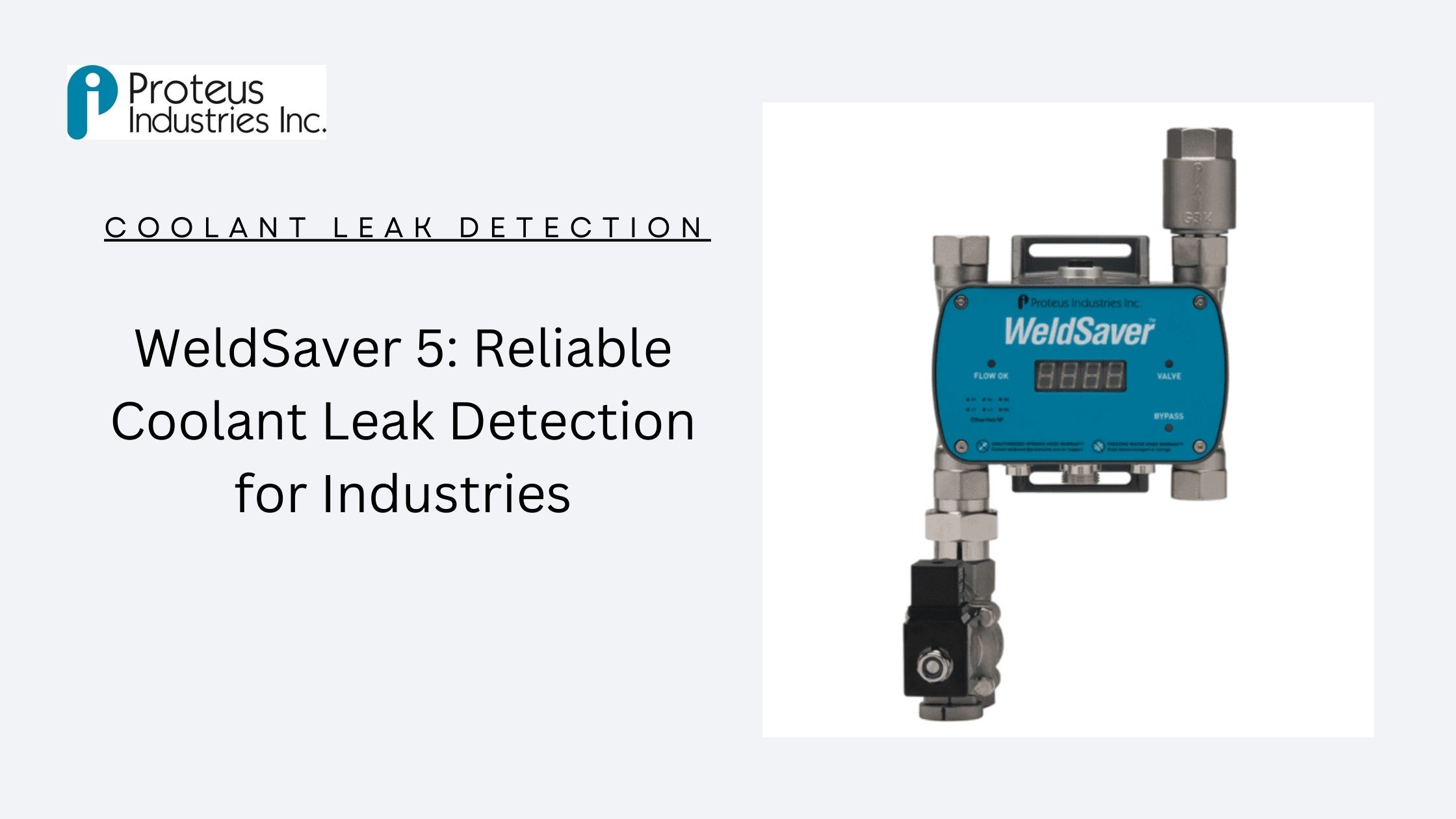

Coolant leaks in industrial environments pose significant safety risks and can lead to costly repairs and operational downtime. As industries demand more efficiency and safety from their machinery, effective coolant leak detection becomes indispensable. This is where the WeldSaver 5 from Proteus Industries shines, offering a comprehensive and reliable solution to safeguard both personnel and equipment.

Understanding Coolant Leak Detection

Before diving into the specifics of the WeldSaver 5, it’s important to understand what coolant leak detection is and why it matters. Coolant systems play a vital role in ensuring machinery operates efficiently by regulating temperature. However, when coolant leaks occur, the system’s performance deteriorates, which can result in overheating, damage to components, and even failure of critical systems.

Coolant leak detection involves using specialized technology to identify leaks early, minimizing potential damage and ensuring smooth operations. In industrial settings, where machinery runs under extreme pressure and temperatures, this technology is crucial for maintaining a safe work environment.

The Role of the WeldSaver 5

The WeldSaver 5 is a state-of-the-art coolant leak detection system designed specifically for high-risk industrial environments. Unlike traditional methods of leak detection, which may involve manual checks or delayed response times, WeldSaver 5 uses advanced sensors and real-time monitoring to detect leaks as soon as they happen.

One of the key features of the WeldSaver 5 is its ability to provide continuous monitoring of coolant flow and temperature. This allows operators to get instant alerts about any potential leaks, enabling them to act swiftly and prevent further damage.

Benefits of Using WeldSaver 5 for Coolant Leak Detection

Preventing Equipment Damage

Coolant leaks can be disastrous for machinery. A small leak can fast escalate into a significant issue, causing severe damage to vital components. The WeldSaver 5 helps prevent this by detecting leaks in real-time, allowing operators to take immediate corrective actions. By addressing leaks early, the system minimizes the risk of expensive repairs or equipment replacements.

Reducing Operational Downtime

Downtime caused by equipment malfunction can be expensive for industries. The WeldSaver 5 helps reduce downtime by ensuring that leaks are promptly detected and repaired before they cause system shutdowns. Its real-time monitoring capabilities allow for quick response times, ensuring that production continues without significant interruptions.

Enhancing Workplace Safety

Coolant leaks also pose safety risks for workers. Leaked coolant can create slippery surfaces, leading to accidents. The WeldSaver 5 mitigates this risk by providing early warnings about coolant issues, ensuring a safer work environment for operators and reducing the chances of workplace injuries.

Advanced Features of WeldSaver 5

The WeldSaver 5 is equipped with several advanced features that set it apart from other leak detection systems:

Real-Time Monitoring Capabilities

WeldSaver 5 provides real-time data on coolant conditions, such as flow rate and temperature. This continuous stream of information ensures that operators have a complete overview of the system’s status at all times.

Integration with Other Safety Systems

One of the standout features of the WeldSaver 5 is its ability to integrate with other safety systems, such as the eVac Coolant Retraction Module. This integration enhances the overall safety infrastructure of industrial operations, providing a holistic approach to coolant management.

Automated Alerts and Responses

When a leak is detected, the WeldSaver 5 immediately triggers alerts, enabling operators to respond quickly. These automated responses can include shutting down machinery or initiating emergency protocols to prevent further damage.

Applications of WeldSaver 5 Across Industries

The versatility of the WeldSaver 5 makes it ideal for use across a wide range of industries. Here are a few examples:

- Manufacturing and Heavy Machinery: In environments where machinery operates under high pressure, the WeldSaver 5 ensures that coolant systems function efficiently and safely.

- Automotive and Aerospace Industries: With the sensitive nature of automotive and aerospace systems, reliable leak detection is critical to maintaining performance and safety standards.

- Energy and Power Generation: In power plants, where coolant systems regulate temperature, the WeldSaver 5 ensures that systems remain operational and prevent potential hazards.

How WeldSaver 5 Enhances Efficiency in Industrial Settings

By integrating smart leak detection technology, the WeldSaver 5 improves operational efficiency. It minimizes downtime and enhances the longevity of machinery by providing timely notifications about coolant issues. This early intervention prevents costly damage and ensures that production lines remain uninterrupted.

Safety Measures and Leak Prevention with WeldSaver 5

Coolant leaks in industrial settings can cause hazardous situations. WeldSaver 5 helps prevent these by offering proactive safety measures. With its continuous monitoring and real-time alerts, the system ensures that leaks are detected and contained before they escalate into larger issues, keeping both equipment and workers safe.

Integration with Other Systems for Optimal Leak Detection

To maximize the effectiveness of leak detection, the WeldSaver 5 can be paired with other advanced systems, such as the eVac Coolant Retraction Module. This synergy creates a comprehensive safety solution that not only detects leaks but also retracts coolant to prevent spills.

Why Choose WeldSaver 5 for Coolant Leak Detection?

The WeldSaver 5 stands out as a reliable and cost-effective solution for coolant leak detection. Its advanced technology, ease of integration, & focus on safety make it the ideal choice for industries looking to enhance their coolant management systems. By choosing the WeldSaver 5, companies can ensure the longevity of their machinery and provide a safer working environment for their staff.

Conclusion

In industrial environments, coolant leak detection is a crucial part of maintaining safety and efficiency. The WeldSaver 5 provides a reliable, real-time solution to identify and address coolant leaks before they cause significant damage. With its advanced monitoring features and ability to integrate with other safety systems, the WeldSaver 5 ensures that industrial operations remain safe and efficient.

For more information on the WeldSaver 5 and how it can help enhance safety in your operations, visit Proteus Industries. Their commitment to providing cutting-edge solutions for coolant leak detection makes them a leader in the field of industrial safety.