Layer adhesion in 3D Printing is a critical index closely related to the inner strength of the printed objects. Appropriate bonding of top layers is needed to create prints that keep working for as long as possible and for the success of these prints during usage. This article will review the definitions of multiple methods and their proper use. This improves 3D layer adhesion, resulting in more robust final prints.

Understanding Layer Adhesion

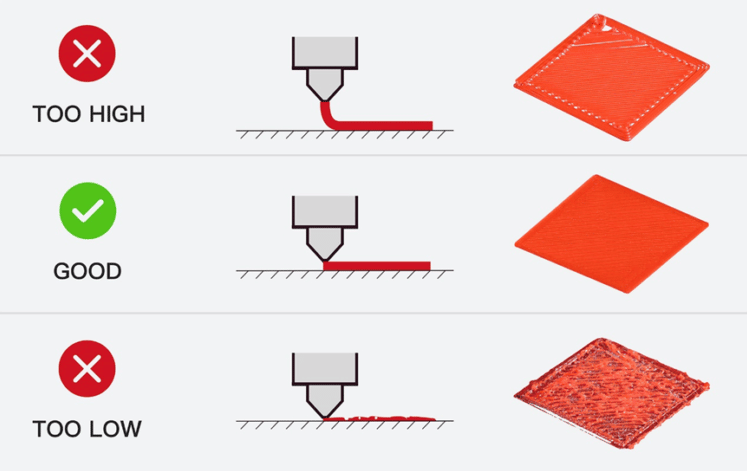

The interface quality between the layers (layer adhesion) ensures that the filament layers “stick” together upon Printing. It is also essential since if the shells need to maintain the proper contacts; then your 3D print may seem fragile. And will fall easily into pieces. Good layer bonding depends on the fact that each layer sticks to the one below it without additional support. Such an interlayer assembly gives a strong and stable object. It is possible to find such factors as the temperature of the print bed or print temperature, print speed, and cooling settings among the factors that affect the adhesion of layers. The ready-made layers will adhere to one another through this adjustment and techniques like incrementing the print speed or heating the build plate. It ultimately led to robust 3D prints.

Techniques for Upgrading the Mechanics of Layer Bonding

Optimizing Print Temperature: Increasing the print temperature to the recommended level can lead to optimal layer sticking. A practical test with a few different temperatures within the recommended range to find the best temperature for tight layer bonding.

Increasing Print Bed Temperature: A warming print bed can improve adhesion between the first layers of filament and the substrate by heating the environment first with the layer. Ensure the bed is at a temperature compatible with the filament used; this will result in an impeccable finish.

Slowing Down Print Speed: Generating the layers too quickly may compromise the adhesion between the layers regarding the shape and complexity of the parts. Decreasing the speed of the printing mode will let each layer bond to its next layer more effectively, which will be more adhesive than the previous layer.

Adjusting Cooling Settings: Although it is crucial to prevent overheating and joining adjacent layers, too-cold situations will cause the bonding to weaken. Practice with temperature parameter settings in your slicer program to find that the distance between cooling and adhesion is good enough for your print’s particular print.

Using Enclosures: Having a cover or an enclosure where the 3D printer is can help stabilize the temperature and humidity, keeping appropriate conditions for Printing. It can contribute to layer abutment, lowering the chance of warping and delamination, and also makes 3D Printing using materials like ABS easier.

Prusa MK3 Silicone Sock

The silicone sock for the Prusa MK3 hotend is the cover to solve the temperature problem of the Prusa MK3 hotend. The sequence used here is made from silicone, which is permeable and fits a hotend tightly. The sock system prevents the temperature from jumping near the hotel, which is crucial for maintaining the fine mesh. It guarantees that temperature does not change when Printing, which may result in an imperfect print. Furthermore, the silicone sock provides a shield layer that eliminates junk or tiny particles that might obstruct the extruder. This conveys that you apply the proper process, and there is almost no chance of encountering some difficulties. Finally, this Prusa MK3 hotend cover is a convenient accessory that helps keep your print temperatures stable. It also prevents prints from getting spoilt.

Conclusion

The adhesion of layers is the crucial factor for quality, as this leads to vigorous and durable prints in 3D Printing by setting appropriate print and print bed temperatures and Printing at higher speed; in combination with correct cooling settings, you may see increased layer adhesion and higher-quality prints by using techniques such as enclosing the printer and utilizing the Prusa MK3 silicone sock. Using a proper methodology, you can be sure that the products of your 3D prints can hold any critical function in any application. Read more blogs here: https://trendingblogsweb.com/