Introduction

Taper bearing Pakistan form the foundation of a variety of mechanical systems, vital to deal with both radial and axial loads with ease. They have experienced significant improvements over time changing in their designs as well as materials and applications. In Pakistan the industry of taper bearings has played an important function, and has significantly impacted the industrial landscape of the country. Let’s take a look at the fascinating story that taper bearing Pakistan have made and explore their historical origins, their technological advances market dynamics, as well as the future of this industry.

Historical Background of Taper Bearing Pakistan

Early Development and Usage

Invention and Initial Applications

The first taper bearing Pakistan was first discovered in the late 19th century, and is largely attributable to the pioneering research that was carried out by Henry Timken. His invention revolutionized the world of bearings by providing an answer that could manage the combined load, thus enhancing the efficiency and durability of machines. In the beginning the bearings were utilized in the growing automobile industry, offering a reliable way to support the wheels of vehicles and components of the drivetrain.

Evolution Through the 20th Century

In the 20th century, taper bearings went through numerous changes. Introduction of novel materials as well as techniques for manufacturing greatly enhanced their performance and durability. This time saw the growth of their application beyond automotive applications, to encompass diverse industrial sectors like mining, railways, and heavy machinery.

Arrival in Pakistan

Early Manufacturing in Pakistan

Production of bearings made from taper in Pakistan began around the middle of the 20th century, spurred by Pakistan’s industrialization efforts. The first manufacturers had to face a variety of challenges such as a lack of access the latest technology and raw materials. Despite these challenges however, the industry built the base for growth in the future by focusing on the needs of consumers and creating important partnerships with suppliers from abroad.

Key Players in the Market

Many companies have risen to prominence in the Pakistani taper bearing market making use of local knowledge and strategic partnerships. Companies like SKF Pakistan and NTN Bearing have played pivotal roles in providing cutting-edge technology and following international quality standards. They have established the bar for their competitors in the industry which has helped create a highly dynamic and competitive setting.

Technological Advancements in Taper Bearings

Materials and Durability Enhancements

Introduction of New Alloys

One of the most significant developments in the taper bearing industry is the creation of novel alloys. These materials have increased the strength and durability of bearings which makes these bearings appropriate for applications that require enough force. In Pakistan manufacturers have adopted these new technologies, making sure that their products comply with the international and local standards.

Coating Technologies

Another important improvement is the application of new coating techniques. Coatings such as titanium Nitride or ceramic layer have been affixed to the bearing’s surfaces to lessen friction and improve longevity. Pakistani manufacturers are increasingly incorporating this technology into their manufacturing processes, supplying high-performance bearings for various industries.

Precision Engineering

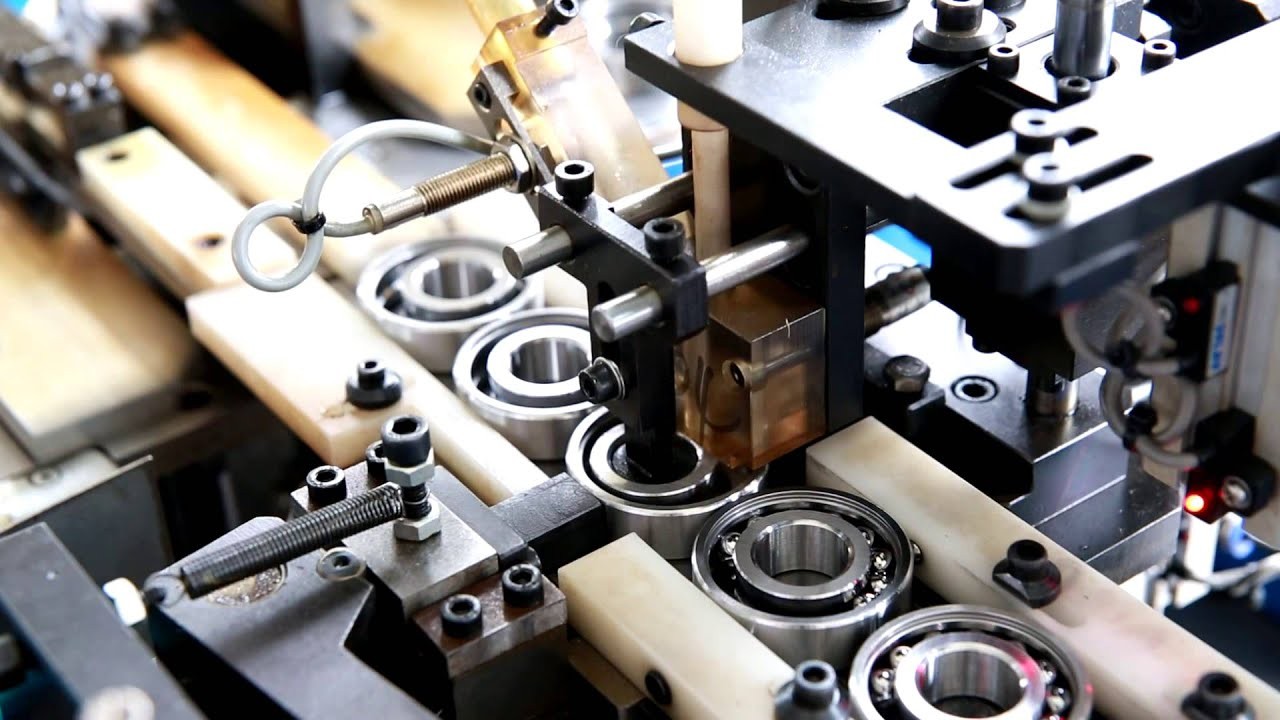

CNC Machining

The introduction of Computer Numerical Control (CNC) machine-tools has revolutionized the production of bearings with taper. This technology permits precise control of the process of machining, resulting in bearings with better tolerances and better performance. For Pakistan, CNC machining has been a common practice for the top manufacturers, which contributes to the production of high-end bearings.

Quality Control Improvements

Control of quality has experienced major advancements with the introduction sophisticated testing and inspection techniques. Techniques like ultrasonic testing, laser measurement and are being used for quality control to warrant the highest levels of accuracy and reliability. These methods have contributed to helping Pakistani producers establish a reputation as a reliable and durable manufacturer of taper bearings.

Market Dynamics in Pakistan

Domestic Production as compared to. Imports

Major Manufacturers

Pakistan is home to several large taper bearing producers who have established a strong local presence. Companies such as Hi-Tech Bearings and Pak Punjab Bearing Industries are renowned for their dedication to innovation and quality. They have built up strong manufacturing capabilities, which have reduced the dependence of the country on import bearings.

Import Statistics

Despite the rise in production in the country, Pakistan still imports a large amount of taper bearings in order to meet the demand for bearings from different sectors. Imports are mostly from countries that are known for their superior bearing technologies like Japan, Germany, and China. The combination of domestic production and imported products assures constant supply of premium bearings for the market.

Key Industries Driving Demand

Automotive Sector

The auto industry is one of the major factors driving demand for taper bearings Pakistan. The increased production of cars and the growing market for spare parts has increased the demand for durable and high-performance bearings. Pakistani manufacturers have adapted their bearings to satisfy the unique needs of this industry to assure compatibility and long-term durability.

Industrial Applications

Beyond automobiles taper bearings are crucial for industrial applications such as mining equipment, machinery as well as railway systems. The strength and versatility of these bearings makes them suitable for heavy-duty tasks which is why they are in widespread usage across a variety of sectors in Pakistan.

Challenges Facing the Industry

Economic Factors

Currency Fluctuations

One of the major difficulties faced by the industry of taper bearings in Pakistan is fluctuation in the currency. Changes in exchange rates can affect the cost of raw materials and import components, which can impact the overall cost of production. Manufacturers have to navigate these economic uncertainties to keep the competitiveness of their products.

Trade Policies

Trade policies have a significant role to play in determining the direction of the industry. Export regulations, import tariffs as well as trade agreements could help or restrict the flow of products and materials. Pakistani producers must be aware of these regulations to improve their supply chains as well as strategies for market entry.

Technological Gaps

Need for R&D Investments

To keep up with technological advancements in the world in technology, the Pakistani industry of taper bearings requires massive investments in the field of research and development (R&D). Innovation is essential to address new challenges and leveraging new opportunities in the market. Businesses that focus on R&D will be ahead of the market with regards to technological advances and product improvements.

Skill Development in Engineering

A well-educated workforce is vital to sustain technological advancement. There is a dire need for a more intensive education and training programs in the fields of manufacturing and engineering disciplines. By encouraging the culture of continual learning and development of skills, Pakistan can assure a constant supply of skilled professionals that will propel this industry ahead.

Future Trends and Innovations

Smart Taper Bearing Pakistan

IoT Integration

Taper bearings Pakistan future is connected in their role in the Internet of Things (IoT). Sensor-equipped bearings are able to offer live data about wear and performance that allows predictive maintenance and decreasing time to repair. Pakistani manufacturers are starting to investigate the possibilities of these technologies and are hoping to provide more sophisticated as well as connected solutions for bearings.

Predictive Maintenance

Predictive maintenance can be a game changer for companies that rely upon taper bearings. By analysing data from smart bearings maintenance teams can anticipate problems before they happen by optimizing maintenance schedules and making sure that disruptions are minimized. This proactive method improves the efficiency and reliability of machinery, which is why it’s an important trend for the near future.

Sustainable Manufacturing

Eco-friendly Materials

Sustainability is becoming more important in the manufacturing industry. The use of environmentally friendly materials for bearing production minimizes environmental impact and helps meet the increasing demand for eco-friendly products. Pakistani producers are exploring alternative options that are sustainable, like biodegradable and recyclable fluids, in order to meet the sustainability goals of the world.

Energy-efficient Production

Efficiency in energy is a crucial component in sustainable manufacturing. When adopting efficient methods and equipment, manufacturers can cut down on their carbon footprint as well as operating expenses. In Pakistan efforts that aim to rise performance in energy use are growing in popularity which is resulting in an environmentally sustainable and competitive industry of taper bearing Pakistan.

Conclusion

The development of the taper bearing Pakistan market is an example of the industry’s adaptability and resilience. From humble beginnings, to adopting advanced technologies, the sector has seen significant progress. While the industry continues to expand due to key technologies and industries and advancements, the future looks bright. By addressing the challenges and taking advantage of opportunities the Pakistani taper bearing industry is set to see an exciting future that is with a focus on sustainability, innovation and international competitiveness.

FAQs

What’s the primary applications of taper bearing Pakistan?

The taper bearings of Pakistan are used primarily in the automotive industry and mining equipment, industrial machinery and railway systems. Their capability to take on linear and axial loads makes them appropriate for diverse applications.

How does the Pakistani market adjusting to the global developments in manufacturing of bearings?

Pakistani producers are increasingly embracing modern technologies like CNC milling, new alloys. And innovative bearing designs to remain ahead of the curve and to meet international standards.

What’s the main problems facing producers of taper bearings from Pakistan?

The biggest challenges are issues with the economy, such as currency fluctuations or trade-related policies. And the need for greater investment in R&D and the development of skills in engineering.

What is the quality of Pakistani taper bearings measure up to the international standard?

The quality of Pakistani taper bearings has been improved dramatically, due to the advancements in engineering, materials and control of quality. The top manufacturers adhere to international standards and guarantee top-quality products.

What are the latest developments expected to impact how taper bearings will be used within Pakistan?

Future developments will include the use of IoT for intelligent bearings and predictive maintenance techniques. As well as sustainable manufacturing practices that focus on sustainable products and efficiency in energy use.

So effective, please book your skardu tour packages now.