Soldering is both an art and a science. Whether you’re an electronics hobbyist, a DIY enthusiast, or a professional technician, having the right tools and knowledge can make the difference between a reliable connection and a failed one. In this article, we’ll delve into the essentials of setting up a soldering station, and offer some tips and tricks to ensure a perfect join every time.

Setting Up Your Soldering Station

A well-organized soldering station is crucial for anyone keen on making reliable and efficient solder connections. Here’s a brief guide to setting up the perfect station:

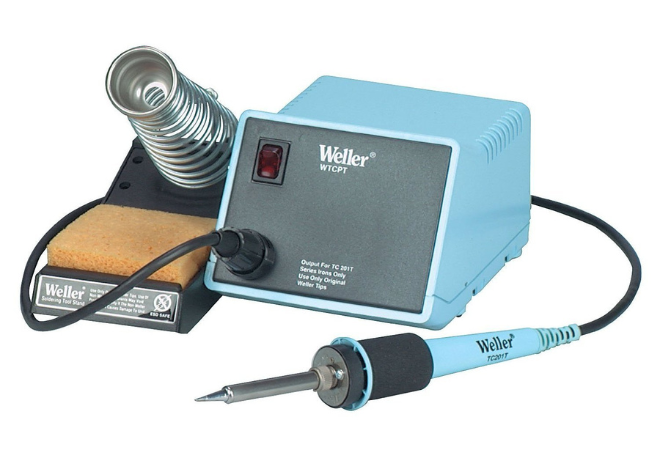

- Choose the Right Soldering Iron: Invest in a soldering iron with variable temperature control. This allows you to adjust the heat for different tasks, protecting sensitive components and ensuring effective joins.

- Pick the Proper Tip: The soldering iron tip plays a pivotal role. A fine tip is ideal for precision, while a broader one suits larger joints. Regularly clean and tin the tip to maintain optimal heat transfer.

- Safety Measures: Never underestimate the importance of safety. Always have a dedicated stand for your soldering iron to prevent accidental burns. Additionally, wearing safety glasses can protect your eyes from potential solder splatters.

- Ventilation is Key: Soldering can emit harmful fumes. Ensure you work in a well-ventilated area, or better yet, use a fume extractor to directly pull away noxious gases.

- Illuminate Your Workspace: Precision work requires clear visibility. An adjustable desk lamp or a soldering station with built-in lighting can make a significant difference.

Tools of the Trade

When diving into soldering, understanding the essential tools can transform the experience from frustrating to seamless. Here’s a snapshot of indispensable soldering tools:

- Solder: For electronics, rosin-core solder is the gold standard. It ensures better solder flow and assists in cleaning the connection, leading to more reliable joins.

- Solder Sucker or Desoldering Wick: These are your go-to tools when a mistake occurs. They help remove excess solder or aid in desoldering components. A solder sucker creates a vacuum to pull away molten solder, while a desoldering wick uses capillary action to soak up unwanted solder.

- Cleaning Sponge and Brass Coil: A clean soldering iron tip is pivotal for efficient soldering. Use a damp sponge for quick cleaning and a brass coil to gently scrub off stubborn residues without damaging the tip.

- Flux: This chemical agent cleans the joint area, ensuring solder flows effortlessly and adheres better. It’s particularly beneficial when working with oxidized or older components.

- Tweezers and Helping Hands: Precision is crucial in soldering, especially with small components. Tweezers aid in placing and adjusting tiny parts, while “helping hands” offer stable support for your workpiece.

Tips for a Perfect Join

Achieving a flawless solder join can be the difference between a functioning circuit and a frustrating failure. To help you master this skill, consider the following tips:

- Prioritize Clean Surfaces: Solder adheres best to clean, oxide-free surfaces. If components or wires appear tarnished or dirty, give them a quick wipe with isopropyl alcohol or a specialized cleaner.

- Embrace Tinning: This preliminary step involves applying a thin layer of solder to the components you’re about to join. Tinning not only makes the final soldering quicker but also ensures a more reliable connection.

- Heat Matters: Always remember to heat the components, not the solder directly. By ensuring both components reach the appropriate temperature, the solder will flow between them, resulting in a strong, solid join.

- Moderation is Key: While it might be tempting to apply a generous amount of solder, it’s essential to resist. Too much solder can lead to “cold joints” which are weak and unreliable. Instead, use just enough to adequately cover the joint.

- Stability Ensures Precision: A shaky hand can disrupt the soldering process. Tools like “helping hands” can provide the necessary stability, especially when working with small components or intricate circuits.

Tricks for Advanced Soldering

For those who’ve mastered basic soldering, advanced techniques can elevate the quality and efficiency of your work. Here are some tricks tailored for the seasoned soldering enthusiast:

- Drag Soldering: A boon for dealing with multi-pin components like ICs. Start by applying flux to the pins. Then, with a blob of solder on your iron’s tip, gently drag it across the pins in a continuous motion. The solder adheres to the pins, forming individual joints without bridges.

- Reflow Soldering: Ideal for surface-mount components. This technique involves placing components on a board with solder paste applied to the pads. The board is then heated using a hot air gun or a specialized oven. As the solder paste melts, it forms reliable connections. This method is beneficial for soldering many components simultaneously.

- Use Heat Sinks: Sensitive components can be damaged by excessive heat. By clipping a heat sink (or even a basic alligator clip) to a component lead, you can divert excess heat away, safeguarding the component.

- Magnifying Inspection: After soldering, especially on densely populated boards, use a magnifying glass or a microscope. This allows for detailed inspection to ensure there aren’t any cold joints, solder bridges, or other anomalies.

- Preheating Boards: For larger boards or ones with significant ground planes, consider using a board preheater. This helps bring the entire board to a uniform temperature, facilitating solder flow and reducing the risk of component damage.

- Solder Masking: If you’re designing your PCBs, using a solder mask can be invaluable. It prevents solder from bridging between closely spaced pads, ensuring cleaner and more precise soldering.

- Flux, Flux, Flux: While beginners might use flux sparingly, advanced soldering often requires liberal application. Flux not only aids solder flow but also helps in avoiding bridges and cold joints.

Conclusion

Soldering is an art form that marries precision with technique. From the meticulous setup of a soldering station, selecting the aptest tools for the task, to mastering the subtleties for the perfect join, every step plays a crucial role in crafting impeccable electronic connections. As one delves deeper into the realm of electronics, advanced soldering tricks reveal themselves to be invaluable assets, further refining one’s skill set.

But beyond tools and techniques, the heart of soldering lies in patience and practice. Like any craft, soldering thrives on repetition, continual learning, and a genuine passion for the process. Each solder joint represents a nexus of knowledge, technique, and dedication.

Furthermore, the soldering journey doesn’t conclude with mastering advanced techniques. The world of electronics is ever-evolving, presenting novel challenges and demanding innovative solutions. Being adaptable, staying updated with new methodologies, and always prioritizing safety and precision will ensure longevity in the craft.

In essence, soldering is more than just connecting components; it’s about forging connections between art, science, and craftsmanship. As you solder on, remember that each join is not only a testament to your skill but also a bridge to boundless electronic possibilities.