When it comes to selecting a prototype PCB manufacturer for your electronic projects, expertise and experience are paramount factors that can significantly impact the success of your endeavors. In this article provided by PCB-togo Electronic, Inc., we delve into the crucial role that expertise plays in prototype PCB manufacturing, the importance of evaluating a manufacturer’s experience in the field, key considerations to keep in mind when choosing a PCB manufacturer, the essential role of quality assurance in production, the benefits of working with specialized manufacturers, strategies for maximizing efficiency and innovation in PCB prototyping, and the collaborative approach necessary for achieving success in electronic manufacturing projects. By understanding and prioritizing these key factors, you can make informed decisions and foster successful partnerships in the realm of prototype PCB manufacturing.

Importance of Expertise in Prototype PCB Manufacturing

The Significance of Specialized Knowledge

When it comes to prototype PCB manufacturing, having expertise in the field is like having the perfect recipe for a successful project. Just like how a master chef knows the exact ingredients and techniques needed for a perfect dish, a manufacturer with specialized knowledge understands the intricacies of PCB design and production.

Impact of Expertise on Prototype PCB Quality

Expertise isn’t just a fancy label; it directly impacts the quality of the prototype PCBs you receive. Think of it as having a seasoned detective solve a case versus a rookie handling it – the experience and know-how make a world of difference in the outcome. Choosing a manufacturer with expertise ensures that your PCBs are crafted with precision and care, leading to top-notch quality.

Evaluating Experience in PCB Manufacturing Companies

Assessing Industry Experience

Experience isn’t just about the number of years a company has been in business; it’s about the depth of knowledge gained during that time. When evaluating PCB manufacturing companies, look beyond the surface and delve into their industry experience. A company that has weathered various challenges and adapted to industry trends is more likely to understand the nuances of your project requirements.

Examining Track Record and Case Studies

Actions speak louder than words, especially in the world of PCB manufacturing. By examining a company’s track record and case studies, you get a glimpse into their past projects and success stories. It’s like checking reviews before trying out a new restaurant – you want to see proof of their capabilities and customer satisfaction before diving in.

Key Considerations When Choosing a Prototype PCB Manufacturer

Understanding Project Requirements

Before selecting a prototype PCB manufacturer, it’s crucial to have a clear understanding of your project requirements. Just like how you wouldn’t buy a size-too-small shoe, you need to ensure that the manufacturer can meet your specific needs and specifications. Whether it’s the size, complexity, or material requirements of your PCB, knowing what you need is the first step in finding the right manufacturer.

Reviewing Manufacturing Capabilities

Not all PCB manufacturers are created equal, and their capabilities can vary greatly. From the technologies they use to the production volumes they can handle, reviewing a manufacturer’s capabilities is like checking if a key fits before turning the lock. Make sure they have the equipment, expertise, and capacity to bring your prototype PCBs to life efficiently and effectively.

The Role of Quality Assurance in Prototype PCB Production

Implementing Quality Control Processes

Quality assurance isn’t just a buzzword; it’s a crucial aspect of prototype PCB production. Imagine buying a car without knowing if it’s passed safety checks – that’s a risky move. Similarly, a manufacturer that implements robust quality control processes ensures that your PCBs meet the highest standards of quality and reliability. From initial design to final testing, quality assurance is the backbone of a successful PCB production process.

Ensuring Compliance with Industry Standards

In the world of PCB manufacturing, compliance with industry standards is like having a golden seal of approval. Just like how a food product with a “certified organic” label gives you peace of mind, choosing a manufacturer that adheres to industry standards ensures that your PCBs are produced with integrity and consistency. By ensuring compliance, you can trust that your prototype PCBs meet the necessary requirements for functionality and safety.

Benefits of Working with a Specialized PCB Manufacturer

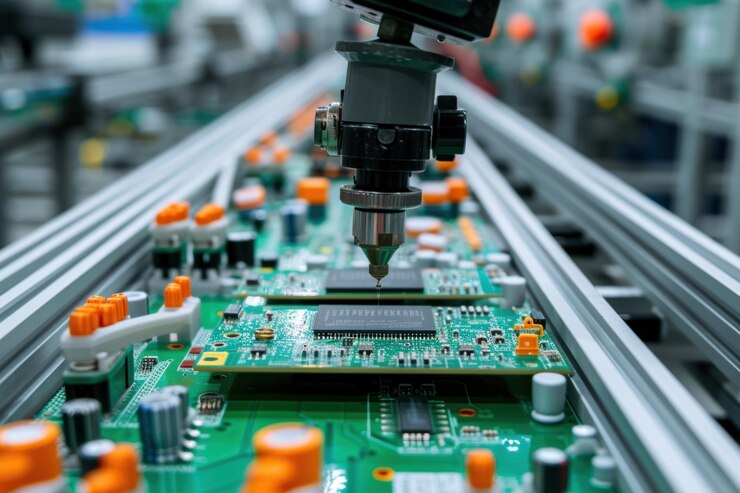

Access to Advanced Technology

When you team up with a specialized PCB manufacturer like PCB-togo Electronic, Inc., you gain access to cutting-edge technology that can take your projects to the next level. Say goodbye to outdated methods and hello to the latest innovations in PCB manufacturing.

Customized Solutions for Unique Projects

Got a project that’s a little out of the box? No problem. A specialized PCB manufacturer, such as PCB-togo Electronic, Inc., can provide customized solutions tailored to your unique needs. Whether it’s a complex design or a specific requirement, they’ve got you covered.

Maximizing Efficiency and Innovation in PCB Prototyping

Streamlining Prototyping Processes

Efficiency is the name of the game when it comes to PCB prototyping. Working with a specialized manufacturer means streamlining your prototyping processes for quicker turnaround times and smoother operations. Get your prototypes done faster and get ahead of the competition.

Fostering a Culture of Innovation

Innovation thrives in an environment that encourages creativity and experimentation. By partnering with a specialized PCB manufacturer like PCB-togo Electronic, Inc., you’re not just getting prototypes – you’re fostering a culture of innovation that can lead to groundbreaking discoveries.

Collaborating with Prototype PCB Manufacturers for Success

Building Strong Partnerships

Success is a team effort, and when you collaborate with a prototype PCB manufacturer, you’re building a strong partnership that can propel your projects forward. Trust, reliability, and shared goals are the foundations of a successful collaboration.

Communication and Feedback in the Manufacturing Process

Effective communication and feedback are essential in any manufacturing process, and working with a prototype PCB manufacturer is no different. With open lines of communication and a feedback-driven approach, you can ensure that your project stays on track and meets your expectations every step of the way.

In conclusion, selecting the right prototype PCB manufacturer is a decision that should not be taken lightly. By prioritizing expertise, evaluating experience, focusing on quality assurance, and fostering collaboration, you can set your electronic projects up for success. Remember, the expertise and experience of your chosen manufacturer can make all the difference in the quality and efficiency of your prototype PCB production. Choose wisely and pave the way for innovation and excellence in your electronic endeavors.

FAQ

1. Why is expertise important when choosing a prototype PCB manufacturer?

Expertise is crucial as it ensures that the manufacturer has the specialized knowledge and skills required to meet your project requirements and deliver high-quality prototype PCBs.

2. How can I evaluate a PCB manufacturer’s experience in the field?

You can assess a manufacturer’s experience by reviewing their track record, case studies, and the industries they have served. Look for indicators of successful projects and satisfied clients.

3. What role does quality assurance play in prototype PCB production?

Quality assurance is essential in maintaining the integrity and reliability of prototype PCBs. It involves implementing rigorous quality control processes to ensure that the manufactured boards meet industry standards and specifications.

4. How can collaboration with a prototype PCB manufacturer enhance project success?

Collaborating with a manufacturer allows for effective communication, feedback, and a tailored approach to meet your project’s unique needs. By working closely with the manufacturer, you can optimize the prototyping process and achieve successful outcomes.