Stainless steel profiles are essential components in construction, manufacturing, and engineering. These profiles come in various shapes and sizes, catering to different industries and applications. The high strength, corrosion resistance, and aesthetic appeal of stainless steel make it a preferred choice for structural and decorative purposes.

Types of Stainless Steel Profiles

Manufacturers produce stainless steel profiles in a range of shapes, each serving a specific function.

Angle Profiles

Angle profiles feature an L-shape, making them ideal for structural frameworks, support brackets, and reinforcements. These profiles offer stability and durability in construction and industrial applications.

Channel Profiles

Channel profiles come in U, C, or J shapes, commonly used in building facades, bridges, and automotive structures. Their design ensures excellent load-bearing capacity while maintaining a lightweight structure.

T-Profiles

T-shaped profiles provide strength in load-bearing applications. These profiles play a significant role in architectural projects and industrial machinery due to their ability to distribute weight efficiently.

Flat Bars

Flat bars serve multiple industries, including shipbuilding, construction, and heavy machinery. Their versatility allows easy fabrication, making them suitable for frames, brackets, and reinforcements.

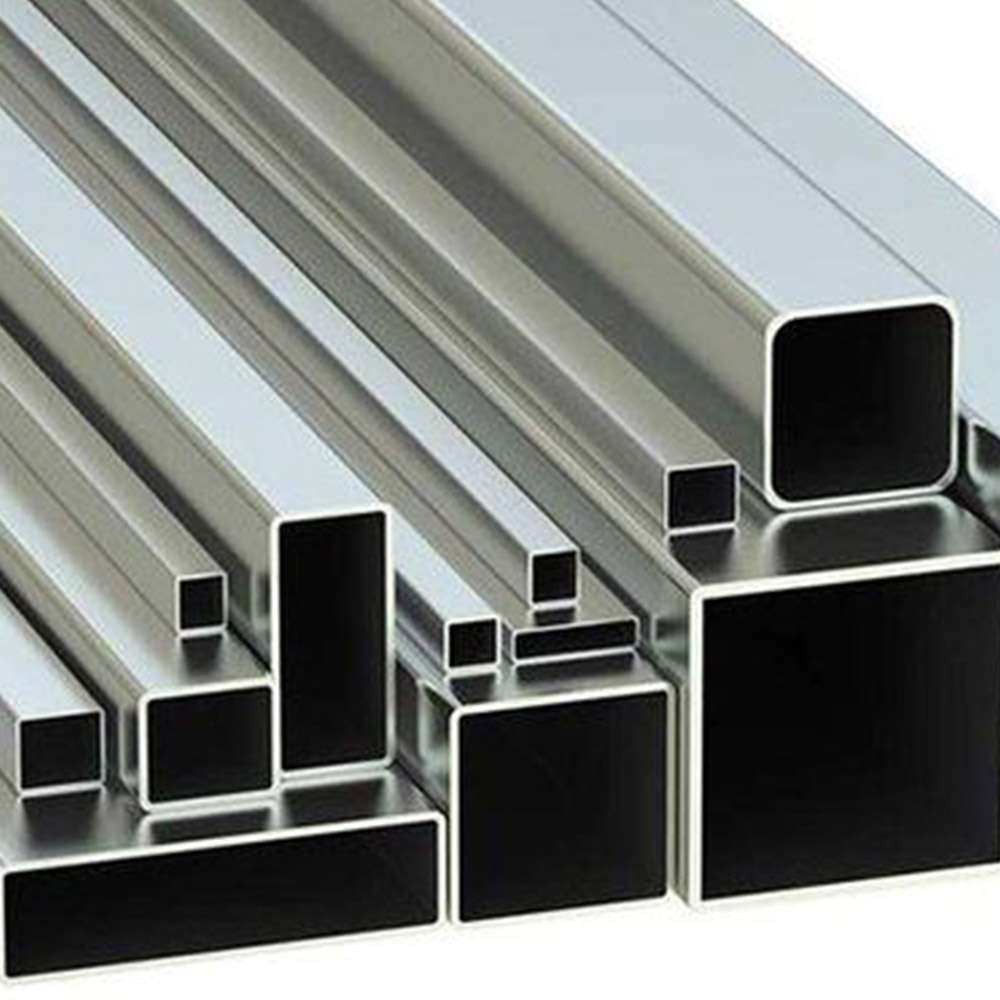

Round and Square Tubes

Stainless steel tubes come in round and square forms, extensively used in handrails, pipelines, furniture, and structural frameworks. Their corrosion-resistant properties make them durable and long-lasting.

Manufacturing Processes of Stainless Steel Profiles

Different methods shape stainless steel into desired profiles, ensuring precision and quality.

Hot Rolling

Hot rolling involves heating stainless steel to high temperatures before passing it through rollers to achieve the required shape. This process enhances mechanical properties, making profiles suitable for structural applications.

Cold Rolling

Cold rolling refines hot-rolled stainless steel by reducing its thickness and enhancing its surface finish. This method produces profiles with higher strength and dimensional accuracy.

Extrusion

Extrusion forces stainless steel through a shaped die, producing complex profiles with high precision. This technique is ideal for customized applications in the aerospace, automotive, and construction industries.

Laser Cutting and Welding

Laser-cut stainless steel profiles maintain precise dimensions and smooth edges. Welding joins different profile sections, creating structures with enhanced durability and strength.

Choosing a Reliable Stainless Steel Profiles Exporter

Selecting the right Stainless Steel Profiles Exporter guarantees high-quality products that meet industry standards. A trusted exporter provides certified profiles with precise dimensions, ensuring durability and performance. Industries rely on experienced suppliers for customized solutions that match their specific requirements.

This introduction highlights the significance of stainless steel profiles in various sectors. Understanding their types, manufacturing processes, features, and applications helps industries make informed decisions when selecting materials for their projects. Reliable exporters play a crucial role in supplying top-quality stainless steel profiles to global markets.

Key Features of Stainless Steel Profiles

Stainless steel profiles offer numerous advantages, making them indispensable in various industries.

Corrosion Resistance

Stainless steel profiles resist rust and corrosion, making them ideal for marine, chemical, and outdoor applications. Their ability to withstand moisture and harsh environments ensures longevity.

High Strength and Durability

These profiles provide exceptional tensile strength, allowing them to bear heavy loads and resist wear. Their durability reduces maintenance costs and extends service life.

Aesthetic Appeal

Architects and designers prefer stainless steel profiles for their sleek, modern appearance. Their polished finish enhances the visual appeal of buildings, interiors, and furniture.

Easy Fabrication and Welding

Manufacturers can cut, bend, and weld stainless steel profiles without compromising strength. This flexibility allows for customization in diverse industrial applications.

Recyclability

Stainless steel profiles support sustainability efforts due to their 100% recyclability. Their eco-friendly nature makes them a preferred material for green construction and manufacturing.

Applications of Stainless Steel Profiles

Different industries rely on stainless steel profiles for structural and functional purposes.

Construction and Architecture

Stainless steel profiles play a vital role in building facades, bridges, and structural frameworks. Their strength and corrosion resistance ensures durability in skyscrapers, stadiums, and commercial complexes.

Automotive and Transportation

Automakers use stainless steel profiles in chassis frames, exhaust systems, and rail tracks. These profiles contribute to vehicle durability, safety, and fuel efficiency.

Aerospace Industry

Aircraft manufacturers integrate stainless steel profiles into fuselages, engine components, and support structures. Their high strength-to-weight ratio enhances performance and longevity.

Marine and Offshore Structures

Stainless steel profiles withstand harsh marine environments, making them essential for shipbuilding, oil rigs, and harbour constructions. Their resistance to saltwater corrosion ensures reliability in extreme conditions.

Food Processing and Medical Equipment

The non-reactive nature of stainless steel makes it suitable for food processing equipment, medical devices, and laboratory instruments. Its hygienic properties prevent contamination and ensure safety.